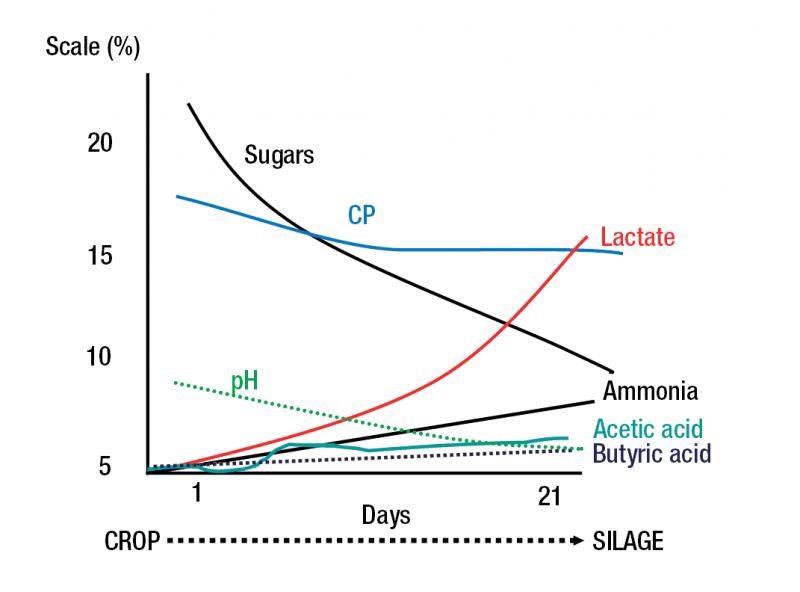

Ensiling involves acidifying, or pickling, the crop. This can be accomplished by direct addition of acid or by fermentation. The ensiling fermentation is an anaerobic process involving the conversion of sugars into organic acids, especially lactic and acetic. These organic acids are produced by bacteria, either present naturally on the crop or added by the use of an inoculant.

The ensiling process can be divided into four phases:

- Aerobic Fermentation

- Anaerobic Fermentation

- Stable Phase

- Feedout phase

Chemical changes during fermentation:

Aerobic Fermentation

During, and after, filling, the forage still contains some entrapped oxygen. Oxygen levels are reduced by:

- Respiration of the plant material

- Growth of aerobic and facultative anaerobic microbes such as yeasts, molds, enterobacteria and lactic acid bacteria (LAB)

LAB can grow and produce lactic acid in aerobic conditions. During this stage, the pH of the silage will start to fall, provided the population of lactic bacteria present is sufficient. During the aerobic stage, plant enzymes like proteases — in particular polysacharrases — will also remain active, leading to increases in soluble protein, ammonia-N and sugars.

Anaerobic Fermentation

Once the silage has become anaerobic, the ensiling fermentation and conversion of forage to silage begins. For a successful initial fermentation — with pH being rapidly reduced below 5 and culminating with a value low enough to achieve a stable product. To achieve this stage, the production of lactic acid as the predominant acid is essential.

The ideal silage pH varies, but a fast, efficient front-end fermentation is mandatory to reduce nutrient losses and prevent bad fermentations. This limits the growth of obligate anaerobic microbes, such as clostridia.

During the initial fermentation phase, the silage composition changes quite dramatically. Thus, feeding new-season silage should be avoided until this phase is completed (at least 30 days) to avoid intake and performance issues.

Stable Phase

Ideally, only little changes occur in the silage during prolonged storage, even under anaerobic conditions. However, when air ingresses into the silage at the margins, aerobic microbes can grow in patches and spoil the silage. Depending on the storage structure, this is typically found in the top, sides and outer layers, which are more susceptible to air infiltration.

In some instances, the silage may contain elevated levels of yeasts that can ferment the lactic acid produced during the fermentation phases to ethanol, causing the silage pH to rise.

In specific, Lactobacillus buchneri can convert lactic acid to acetic acid during the anaerobic silage environment — causing an increase in the silage pH — during the storage phase. Acetic acid has good antifungal properties and can help to control the spoilage, lactate assimilating yeast populations.

In this phase, acid tolerant enzymes — such as protease and cellulases — can remain active. There may be increases in soluble protein (ammonia) during the storage period. Other types of microbes can form resistant spores — such as molds, clostridia and bacilli — that enable them to survive in a dormant state in the silage.

Fast filling, high packing density and maintenance for the specific type of ensiling storage structure is critical.

Feedout Phase

As silage is opened and fed, it is once again exposed to air and to aerobic organisms that survived the ensiling process —bacilli, yeasts and molds. In most situations, this aerobic growth at feedout will be initially dominated by yeasts. As these aerobic organisms grow, nutrients are lost from the silage, and the material can become badly spoiled, and even contaminated with toxins and undesirable microbes such as clostridia and listeria.

The rate and extent of this spoilage is dependent on the:

- Extent of air ingress is governed, which can be limited by achieving sufficient silage density during packing and by good management of feedout

- Levels of spoilage organisms in the stored silage, which can be managed with good harvest protocols

- Factors that affect the speed at which the aerobic phase is completed, such as filling speed, packing density, speed and efficiency of silo sealing, etc.

- Use of inoculants proven to reduce their numbers in the silage