With high input costs, it is now more important than ever for farm profitability that homegrown corn silages produce the best feed quality possible.

Many producers are unaware that poorly managed and untreated corn can be subjected to significant losses of nutritional quality and physical dry matter (DM) of 20% or greater, and, in a time where purchased feed costs are so high, this can have a devasting impact on farm profitability.

Many producers believe that corn silage will ferment quite adequately naturally due to the high sugar content and easy-to-ensile nature of the crop. However, the advent of new DNA analytical methods such as metagenomics allows us to study the abundance of all the different types of bacteria found on corn for the first time. This insight suggests corn silage is no different than other forages when trying to produce the best quality silage.

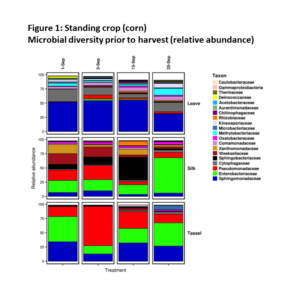

Over just a short growing period, the microbial diversity of standing corn silage can change significantly week to week, and many factors such as weather and field management can play a part in this.

Table 1. The microbial diversity of standing corn silage can change significantly week to week, and many factors such as weather and field management can play a part in this. The different colored bars in the table represent different types of bacteria in a standing crop of corn, the bigger the bar the greater the abundance of that particular type of bacteria. Many of these bacteria can be undesirable with regards to making good quality silage. When it’s time to cut silage, growers take a risk if they do not treat the corn to prevent undesirable bacteria from dominating the fermentation — and the result may be a poorly fermented silage.

Poorly fermented corn silage will lose dry matter both through the ensiling period due to undesirable bacterial growth and through increased spoilage when the silage opened due to poor stability, in which yeast and molds cause the silage to heat and deteriorate dramatically in quality and feed value. This has a significant impact on costs as this lost silage needs to be replaced with purchased feeds.

Treating corn silage with a condition specific inoculant that has been independently trialed and proven to overcome the microbial biodiversity seen in the standing crop. This helps maintain the corn silage quality and reduces DM losses through the fermentation. Plus, it reduces losses due to instability by actively inhibiting the growth of yeasts and molds.

In table 2. The abundance and types of bacteria found in the corn silage changes greatly in silage treated with MAGNIVA Platinum 1 compared to an untreated control over 64 days. In the MAGNIVA Platinum 1 silage, the abundance of desirable Lactobacillus populations (blue bars), increased much more quickly than the control. At 64 days ensiling, the only type of bacteria to be found in the treated silage was Lactobacillus. This results in a silage with a reduced risk of heating or spoiling.

The control samples contain a far higher diversity of different types of bacteria, meaning it is more likely to encounter undesirable bacterial growth, reducing the fermentation efficiency and increasing the risk of DM and nutrient loss in the silage and increasing the risk of aerobic instability when opened for feeding.

Managing feed costs is crucial to achieving on-farm profitability. Quality silage plays a significant role in driving efficient production.

- Corn silage is the number one energy consumable on most dairy operations.

- The controlled fermentation of corn helps to preserves this energy and nutritional value and prevents dry matter losses and spoilage.

- Why risk up to 20 percent of your silage’s dry matter. Think of it as losing every sixth load of silage that comes through your farm gate?

WHY USE A MAGNIVA CORN INOCULANT?