Silage Heating

Heating is a natural result of the fermentation process that occurs during ensiling. However, sometimes this process can become unstable, with significant heating. When this occurs, valuable dry matter (DM) can be lost.

At harvest, oxygen and microorganisms are trapped within the forage. These two factors cause exothermic fermentations — producing heat — only stopping when the oxygen is consumed or the microorganisms are killed or dormant. During this period, temperature can rise up to 122° to 140° F, or 50 to 60° C. The final temperature depends on:

- Oxygen quantity (related to density)

- Microorganism contamination

- The initial temperature of forage at harvest, which can vary

This heating phase is unavoidable and indispensable to the ensiling process. However, forages correctly harvested and ensiled are less affected. If heating lasts too long, it can have a negative impact on forage protein quality and reduce the DM available.

Once this heating phase is complete, the silage doesn’t cool instantly. The time required to cool down the mass depends on:

- Ambient temperature at harvest

- Maximum temperature reached

- Quantity of silage

- Density of silage

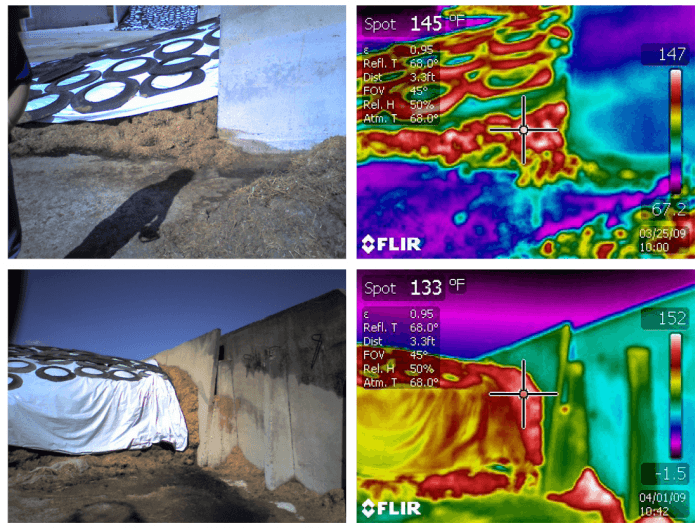

What you see on the silage face may not always tell the full story. Forward Looking Infra-Red (FLIR) imaging can reveal “hotspots” or areas where feed temperature may affect preservation and feed quality. The FLIR examples below show typical storage situations where heating issues may not always be evident.

Signs of Excessive Silage Heating

Heat doesn’t always signal spoilage. Warm silage may be the result of a high ambient temperature without a fermentation event.

Warning signs of excessive silage heating include:

- Heat

- Mold growth

- Spoilage — Where there is spoilage, there have already been significant DM losses and increases in temperature

- Mustiness on the face or surface

- Caramel or tobacco smell

- Dark brown to black color

Risks for Silage Heating

Heating most often occurs at two points in the ensiling process:

- During filling and shortly after silage is enclosed microorganisms begin to grow and produce heat naturally, due to exothermic (heat generating) biochemical processes. When the oxygen within the silage is consumed, the rate of temperature increase slows. The final temperature depends on oxygen availability and the types of microorganisms that dominate in the crop.

- After silage is opened exposure to oxygen reactivates aerobic growth, which produces heat. The intensity and speed of this heating depends on the level of yeasts and molds present, speed of feedout, silage density and environmental conditions. This heating phase can continue even after the silage is moved to the bunker for feeding.

The risks for excessive silage heating and spoilage can increase when:

- Plants are harvested at increasing maturity levels

- Crops are damaged from hail, insects or frost

- Plants are stressed from drought, for example:

- Crops are ensiled with greater than 1,000,000 (106) colony-forming units (CFUs) of yeast per gram of fresh forage

Challenges with Silage Heating

Each 15° F, or 9° C, rise in temperature on one ton of 30 percent DM silage requires over 12.6 MCal of energy — energy that cannot be used by animals.

Other challenges from silage heating include:

- Increased DM losses

- Lost forage nutrients (energy, protein and digestibility)

- Drop in sanitary quality

- Lowered animal performance

- Mycotoxins

- Increased feed refusals due to poor palatability

Preventing Silage Heating

Good silage management is critical to ensuring valuable DM and forage nutrients aren’t lost to heating events. To help prevent silage heating:

- Use a research-proven heterofermentative forage inoculant

- Correctly pack and fill the silage storage structure

- Properly cover with good-quality plastic

- Seal the structure as soon as possible after filing

- Feed out silage at the proper rate

- Use good face management

Managing Silage Heating

Always discard spoiled or moldy silage. In particular, avoid feeding spoiled silages to pre-fresh and post-fresh dairy cows.