As a forage crop, alfalfa has high palatability, high protein levels, good winter hardiness and good drought tolerance. However, this nutritional value comes with a price. Alfalfa requires well-drained soils with high fertility and pH.

Compared with alfalfa dry hay, alfalfa silage typically preserves more nutrients due to reduced leaf losses. In addition, weather damage is easier to avoid since it requires less time wilting on the field to achieve the target dry matter (DM) level. Wetter feeds also are more palatable and digestible for cattle, especially in dry, hot climate conditions. Alfalfa silage is better suited for use in total mixed rations (TMRs) for ruminants.

Maturity

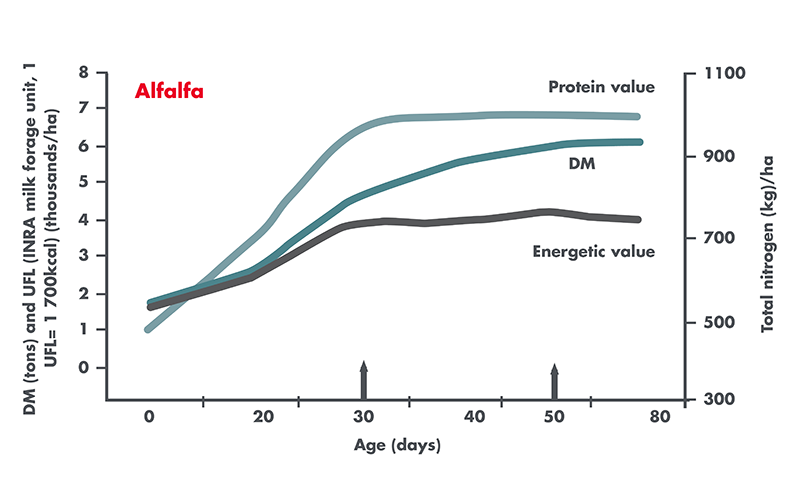

Yield and quality are major factors to consider when harvesting alfalfa. As the plants mature in the field, total yield rises, and quality lowers. During spring growth, each day the harvest is delayed, resulting in a decline in quality. The harvest schedule during the first two cuttings should be optimized to maintain reasonable yields while maximizing the quality of forage.

The decline in alfalfa quality also is a result of the changes in the leaf-to-stem ratio (stem elongation). There is greater accumulation of fiber and lignin and, proportionally, less protein. A greater proportion of neutral detergent fiber (NDF) is associated with the stem and results in lower digestibility. There is likely to be a fiber effect, lowering animal intake due to rumen fill, and lowering digestibility due to greater lignin accumulation.

Evolution of quantity of dry matter vs. protein and energy value of alfalfa:

A helpful tool to evaluate the stage of growth of the alfalfa is the predictive equations for alfalfa quality (PEAQ) stick. It uses the longest stem and the most mature stem to estimate the NDF of the alfalfa in a standing crop:

Dry Matter

Alfalfa begins to lose sugars soon after it is mowed, and sugars are the food of fermentation bacteria. The key to high-quality alfalfa silage is to dry the crop to the proper DM level for ensiling in the respective storage structure as quickly as possible.

| Alfalfa: | Harvest Stage | DM Level |

|---|---|---|

| Bunker or Bag | bud - 1/10 bloom | 35-45% |

| Stave | bud - 1/10 bloom | 40-55% |

| Harvestore | bud - 1/10 bloom | 50-70% |

| Wrapped Bales | bud - 1/10 bloom | 40-60% |

If the alfalfa is harvested and ensiled when it’s too wet, there is the risk of prolonged fermentation, which can result in DM losses and a high acid load. Also, the chance of clostridial fermentation elevates.

If the alfalfa is ensiled too dry, it makes proper packing difficult. The trapped air leads to increased plant respiration and production of heat. It also allows the metabolism of aerobic microbes (e.g. molds), and aerobic instability increases. This can decrease the amount of protein available to the animal. It is important to wilt to the appropriate DM level prior to ensiling.

Chop Height

The University of Wisconsin recommends cutting healthy, non-stressed alfalfa at a 3-inch, or 7.5-cm., cutting height to achieve maximum DM and nutrient yields. The use of roller conditioners is an option to minimize field losses and speed up the wilting process.

Above 30% DM, do not cut more than a 0.5 inch, or 1.5 cm. This chop height requires good control of the fiber efficiency and fermentation process. Below 30% DM, there is less risk of spoilage, and a higher chop length could be used — between a 0.75 inch to 2 inches, or 2 to 5 cm.

Mowing

Leaving the mowed forage in wide swaths will result in much faster drying and better conservation of plant sugars. Hay crops normally have a lower sugar concentration than corn, so conserving plant sugars is important.

Cutting alfalfa in the afternoon following a sunny morning results in higher forage sugar levels, but much of these sugars are lost if the forage remains in the windrow for prolonged periods of time. Wilting times vary depending on the storage structure to be used. See above table for target DM levels.

The first cutting is a major challenge and sets the pace for the season harvest schedule. In Northern climates, the first cutting can represent 30 to 40% of the total season DM yield. A good balance of quality and quantity is essential. Harvest delays can be incredibly costly since there is a great amount of forage in the field quickly losing quality. It’s estimated that each day the harvest is delayed it results in a quality drop of 5 points in relative feed value (RFV) or relative feed quality (RFQ).

Additionally, there could be cool-season grasses in the alfalfa stand past the heading stage, which can further plummet forage quality.

Pack Density

It is vital to properly pack silage to achieve an anaerobic environment rapidly after harvesting and thus reduce DM loss. Silage porosity is determined by packing density and DM content. It determines the rate that air can infiltrate the silo. As a general rule, the minimum pack density for alfalfa silage is recommend at: 15 lbs. per DM/ft3, or 200 to 250 kg DM/m3, or a porosity below 40%.

Challenges

Soil, or ash, contamination is common in alfalfa silage. Excess ash can raise the risk of impaired fermentation and spoiled silage. Producers should aim to keep ash content below 10% DM for alfalfa silage by:

- Planting varieties that stand better

- Harvesting earlier

- Raising the cutter bar

- Using flat knives

- Keeping the windrow off the ground

- Keeping rake tines from touching the ground

- Minimizing movement of hay horizontally

- Using a windrow merger; and storing silage on concrete or asphalt

Due to its lower sugar levels, spoilage on the face and overall bunk life of alfalfa silage is usually less of a problem compared with corn silage. However, butyric acid formation in low DM forages is a greater problem when there is a shortage of soluble sugars in the forages.

Wheel damage is an overlooked source of plant damage in the field. Use traffic-tolerant varieties and avoid unnecessary trips across the field. Also consider using small tractors and avoid duals.

A critical component to high-quality silage is a rapid drop in pH. Alfalfa silage typically has a higher buffering capacity, or resistant to a change in pH. This resistance is determined by plant components such as organic compounds, crude protein and cations such as potassium. Therefore, the use of a research-proven forage inoculant is important to creating high-quality silage. Click here for more information on inoculant choices.

Additional Reading

Check out these resources written by silage experts for more information on creating alfalfa silage.