Today, producers have a variety of tests available to help adjust management practices and avoid future problems altogether. There are various important tests producers should consider conducting — from prior to harvest to after ensiling is complete.

Testing for Nitrogen content

Excess nitrates accumulated in cereal grains and forages — like sorghum and sudangrass — can result in chronic or acute toxicity; can have a dramatic effect on animal performance; and can also lead to the production of deadly silo gases. Grass should be regularly checked prior to cutting to ensure nitrate levels are below 0.1% (1,000 ppm). The ensiling process can lower the nitrate levels in forages by about 50%.

Testing for Dry Matter Content

Harvesting forage crops outside optimal dry matter (DM) ranges can set the stage for many challenges. Testing for DM content prior to harvest and ensiling is a critical step.

DM is measured as weight difference between the forage fresh (as is) and dried in an oven, a microwave oven or using a Koster tester.

To measure DM using a Koster tester, place 100 grams of the sample in the container and switch on the power for about 30 minutes. Weigh the sample, and if no more weight is lost (as moisture), the final DM level can be calculated.

The dry matter content is calculated as:

Dry Matter (DM) = (Dry weight/ Fresh Weight) x 100 % Moisture content (%) is obtained by: 100 – % DM = % moisture

Weighing and sample high-moisture corn for DM levels:

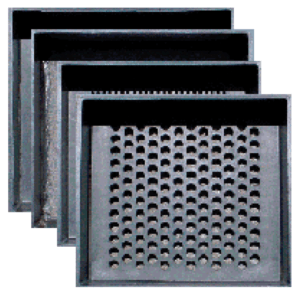

NASCO®’s Penn State Forage Particle Separator

Actual chop length can be monitored in the field by using NASCO’s Penn State Forage Particle Separator. Ideally, after sieving the material should be distributed as follows for corn silage fed to lactating dairy cows:

| Screen (in) | Screen (mm) | Corn silage sieving distribution for ruminants |

|---|---|---|

| 0.75 | 19 | 3-8% |

| 0.31 | 8 | 45-65% |

| 0.16 | 4 | 20-30% |

| Pan | Pan | < 10% |

NASCO’s Penn State Forage Particle Separator:

Taking a Silage Sample

The objective when collecting a silage sample for DM or laboratory analysis is to obtain a sample representative of all silage that will be fed. This is important because silage varies considerably throughout the face of the silo.

The best way to collect a sample for laboratory analysis is to:

- Subsample the pile of feed that has been defaced from the entire silo (including that at the bottom of the face), and pushed into a central pile and either mixed with the loader bucket or briefly mixed in the mixer wagon and discharged.

- Walk around the pile, collecting forage with a scoop, or using your hand in a scooping motion, to collect forage from at least 10 locations, and place the forage into a large bucket.

- Dump the collected forage onto a clean, dry surface and mix it with a scoop shovel.

- Divide the forage pile into four quadrants by drawing lines in the forage pile with your finger.

- Subsample with your scoop from each of the four quadrants and submit this sample for analysis.

Care should be taken to use a scoop or to grab all silage particles “scooped” by your hand. Otherwise, fine particles can be left behind.

If the whole face is not being fed each day, then a “W” should be drawn across the face, and a sample taken from three spots across each arm of the “W” to make a representative sample.

Interpreting Sample Analysis

Acetic acid:

Acetic acid is a good antifungal compound and can enhance the aerobic stability of silages. Ideally it is produced from inoculation with Lactobacillus buchneri during the storage phase.

Acid Detergent Fiber (ADF), Neutral Detergent Fiber (NDF) and Lignin:

These values should be within average ranges for the type of material harvested. If levels are higher than normal for the crop, it may be a sign the material was more mature than ideal. This can also lead to yeast and mold challenges.

Acid Detergent Insoluble Crude Protein (ADICP):

High levels of bound protein — ADICP, greater than 10 % of the CP — show there has been excessive heat of fermentation-produced heating in the silage.

Ash Levels:

Ash — from the plant or soil contamination — levels can be determined after harvest with additional testing. Normal levels in the plant should be around 6 % to 8 %, depending on the crop. Higher numbers can indicate slurry contamination. Soil can contain clostridial, spores and enterobacteria, which can be become a challenge to overcome.

Butryic and Iso-Butyic Acids:

Levels of this acid should always be low. The typical goals are less than 10 % of the lactate levels and less than 1 % overall concentration.

Crude protein (CP):

The higher the protein level, the higher the buffering in the material and the more acid is required to bring the pH down. This can facilitate complications from clostridia.

Lactic Acid:

This is the main driver for pH drop and should be at a reasonably high level for the silage pH to rapidly stabilize. This number can vary with the crop ensiled and DM level.

NDF digestibility (NDF-D):

NDF-D can be estimated based on the lignin content but also determined via ruminal incubation (in-vitro and in-situ). NDF-D has a large impact on the energy value of the forage as well as animal intake and performance.

Potassium:

High potassium forages (greater than 2.5 %), result in cationic diets and are not desirable to feed immediately prior to calving for ruminant animals.

Soluble Protein:

High levels of soluble protein indicate there has been protein breakdown, also called proteolysis. This can occur due to prolonged wilting in the field or inefficient silage fermentation.

Starch:

The ideal starch content varies according to crop. Starch levels are a good indicator of timing of harvest.

Labs can measure starch digestibility using seven-hour testing of in-vitro starch digestibility. This is also now readily predictable by near-infrared reflectance spectroscopy (NIRS). To help avoid the risk of acidosis, it is recommended to test for starch digestibility and adjust the ration accordingly.

Yeasts and Molds:

Producers should expect heating if levels are above 100,000 colony-forming units (CFUs) .

Avoid feeding the silage if high levels of mold are identified.

Additional Reading

Check out these resources written by silage experts for more information on silage tests:

- Taking forage samples (Tips for Taking Forage Samples, FJ Quality Silage)

- Guidelines for on-farm silage evaluations, FUSE023 (Corn Cob Drive)

- Silage Sampling, TB F4053a, Updated/Unapproved (Corn Cob Drive)

- Analysis Request Form (Corn Cob Drive)