Homegrown cereals — such as barley, sorghum, triticale and wheat — can play a big part in reducing overall feed costs and improving profit margins. Moist, crimped cereals can be harvested earlier and passed through a special crimping machine that cracks the grain to expose the starch. The early harvesting window of crimped cereals maximizes dry matter (DM) yield and allows a following crop to be established sooner. Crimped cereal also reduces the costs of drying grain.

The high-starch and low-acid levels of crimped cereal results in good feeding values and makes it an ideal complement to feeding grass silage or haylage. Crimped cereal can also be a good source of digestible fiber.

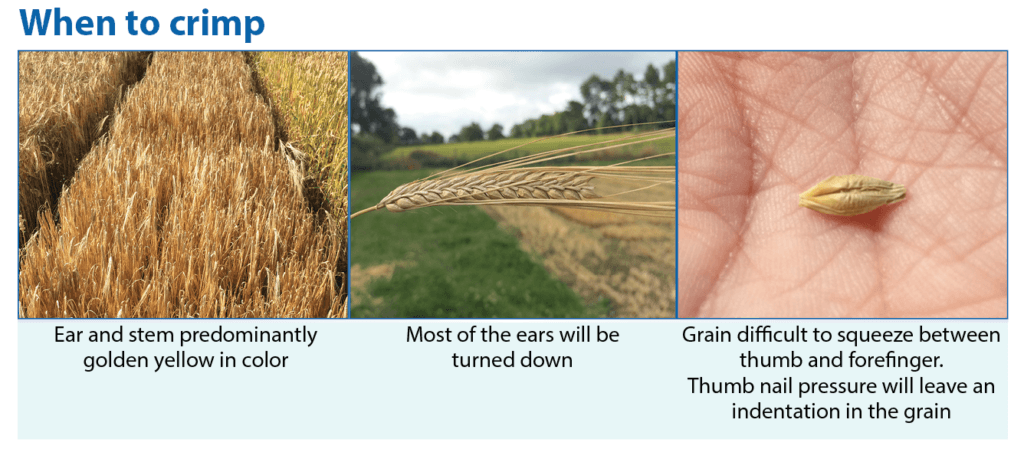

Maturity and Dry Matter

Moist-crimped cereals can be harvested earlier — around 25 to 40% moisture — and processed by the crimping machine.

| Harvest Options | Crop DM % | Crop Color | Stem Color | Ear Color | Grain Texture |

|---|---|---|---|---|---|

| Fermented high DM milled wholecrop / start of crimping | 50-60 | Yellow | Mainly yellow, trace of green at the node | Yellow | Hard cheddar, thumbnail impression held |

| Fermented high DM milled wholecrop / crimping | 60-70 | Yellow/gold | Mainly yellow, trace of green at the node | Yellow/gold with some ears turned down | Very hard cheddar, grain pierced with thumbnail |

| Crimping / end of fermented high DM / milled wholecrop | 70-80 | Yellow/brown | Yellow | Gold, turned down | Hard, some grain, pierced with thumbnail, others impossible |

Challenges

Due to the high DM and starch content of crimped grain, aerobic instability caused by yeasts and molds can affect feedout quality. New inoculant technology has played a big part in successfully ensiling this challenging crop.

Learn more about forage inoculant choices for crimped cereal.