Feedout can be a challenging time. The silage is opened and exposed to air (oxygen). In the presence of oxygen, yeasts and molds that were dormant in the anaerobic environment can become active. This growth is the primary cause of silage heating, which can result in dry matter (DM) and energy losses.

Proper feedout management helps maintain the integrity of the silage structure and retain the maximum amount of nutrients.

Limiting Feedout Losses

When feeding out silage, be sure to:

- Remove all spoiled silage

- Keep the silage face vertical and tight

- Remove enough silage to avoid any heating and do not pile silage overnight ahead of feeding

- Premix the silage that has been obtained from the entire face with the loader bucket or mixer wagon prior to feeding

- Strive to have as little loose silage at the end of feeding as possible

- Keep the leading edge of plastic sufficiently weighted down to prevent air infiltration beneath the plastic

- Remove plastic at least twice weekly, or as often as necessary, so that top spoilage does not occur prior to feeding

Removing Silage

For horizontal silos, maintain a tight slightly concave [from top to bottom] surface that avoids dangerous silage overhangs.

Cut silage from the face rather than tear it. Tearing increases the intake of air into the silage, promoting the development of aerobic microorganisms.

Bunk defacer: Ideally, remove silage using a bunk defacer. Defacers:

- Do not cause fracture lines that allow air into the silo

- Mix the silage from across the height of the silo, reducing ration variability

- Break up haylage clumps, which can reduce mixing time

- Leave a straight face, which does not catch water

- Can cause less damage to the silo equipment used to remove silage from the bunker

Loader bucket: Another method of silage removal is using a loader bucket. This can lead to significant disruption of the silage face. As the face is disrupted, more air is allowed behind into the silage. This can lead to ongoing instability of the silage and a constant reduction in the feed value, DM intake of the silage as palatability lowers. If using a loader bucket to remove silage, preferably shave across the width of the silo.

Silage rake: The silage rake is attached to a telehandler and scrapes the silage from the face, allowing the removal of a relatively narrow layer of silage to be removed without reducing the silage face density. It is not as effective as using a defacer. However, the system is suitable for use on all bunkers and piles. Rakes are not suitable for silage bags.

Block cutter: Block cutters help maintain the integrity and density of the silage face but generally lead to a slight loosening of the silage. Block cutters may remove an entire section of the face or a defined block volume. The depth of the block removed is significant, which means the face may be crossed relatively slowly. Variability in the ration can occur if the entire face is not crossed daily.

Feeding Silage

Feed silage at an appropriate rate. Removing too much silage unnecessarily exposes it to oxygen for longer periods.

Commonly recommended feedout rates are:

- 6 to 12 inches, or 15 cm., of silage per day from a bag, bunker or pile face with feedout reaching the higher end of the range during warmer temperatures or with lower density ranges

- 4 inches, or 10 cm., per day in summer, 2 inches, or 5 cm., per day in winter, for upright silos

In the case of heating, protect the open front with a thick net, which will keep silage in the shade while allowing air to circulate. This technique also helps protect the silage from birds. Protection of the front with a cover creates a hot, damp atmosphere favorable to mold growth. This practice should be avoided.

Managing Spoiled Silage

It is common for silage to spoil due to air ingress. Typically, these locations include the top and sides of the silo, also balls or chunks in the main body of the silo. Observe and smell layers of silage within the storage structure. Watch for layers that went through clostridial or abnormal fermentations and remove these layers.

Discard spoiled silage away from the storage structure. Placing waste close to the useable silage may result in perpetual inoculation of the open front of the silage face or clamp.

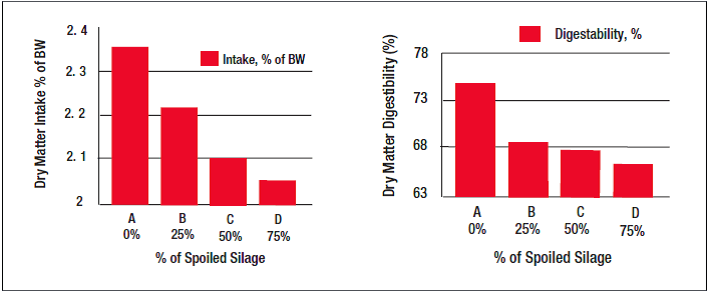

Do not feed spoiled silage. Including spoiled silage in a ration has been shown to lessen animal intake and production. For example, molds in cattle feed can cause respiratory problems, reduce intake and negatively affect production. Plus, some common spoilage molds may produce mycotoxins that can cause more serious health issues.

The effect of feeding spoiled silage on dry matter intake and total ration dry matter digestibility

Whitlock L.A., Wistuba T., Siefers M.K., Pope R.V., Brent B.E., Bolsen K.K. Effect of level of surface-spoiled silage on the nutritive value of corn silage-based rations. Cattlemen’s Day, 2000.

Some forage inoculants can help improve aerobic stability as well as prevent yeast and mold spoilage. For more information on forage inoculants, click here.