A new UK-based trial undertaken at Reading University indicates that using an inoculant on grass silage can improve bunker stability,

increase feedable dry matter (DM) by 29% and improve fat-corrected milk yields by 1.9 kg/day.

Lee Gresham, UK and Ireland country manager at Lallemand Animal Nutrition, explains the trial shows how the use of a crop- and condition-specific inoculant on UK grass silage can offer massive benefits on farm.

Gresham explains the trial used 28% DM grass harvested in April.

Half the crop was treated with MAGNIVA Platinum 3, and the other half was left untreated.

The trial looked at how the inoculant impacted the grass’ fermentation, locked in nutrients and how this translated into cow performance when feeding the silage.

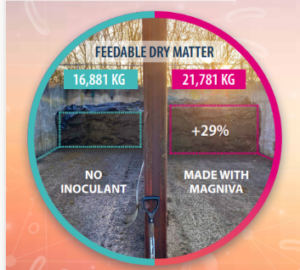

Inoculant increased feedable dry matter in silage by 29%

“There were significantly higher dry matter losses in the control bunker than the treated bunker, which means there was less silage available for the cows,” he says.

“Due to the dry matter losses, the untreated bunker shrunk considerably more than the treated bunker, equating to 29% more feedable dry matter,” Gresham explains.

Better silage increased palatability for cows

The fermentation results from the two bunkers showed that the treated silage had superior lactic, acetic and propane diol acid profiles — plus 10 times less butyric acid.

“The lower butyric acid in the treated silage indicates that clostridia, the bacteria that break down protein and cause foul-smelling silage, were effectively inhibited. This resulted in a more palatable silage, which was evident in the increased dry matter intake seen in the group of cows receiving treated silage in their ration,” he says.

More stable silage increases energy available for cows to make milk

Aerobic stability was also improved in the treated silage. This resulted in less heating in the bunker, reducing the energy lost to the environment as heat instead of being turned into milk by the cows. This energy loss is caused by aerobic spoilage that occurs when air gets into the bunker and activates spoilage microbes, including yeasts and moulds.

“The control bunker temperatures peaked at 34.6o C, whereas the treated silage reached only 26.7oC — a significant difference in energy terms.”

“This extra 8o C of heating in the control group is the equivalent of losing 28MJ of energy for every tonne of silage fresh weight that is unstable. This equates to 5.4kg of milk lost,” he says.

Treated silage increased DM intakes, milk yields, fat and protein

Gresham says significant improvements were also seen in performance when cows were fed the treated silage.

“The well preserved and stable treated silage resulted in a significant increase in dry matter intake by 1.5 kg/day compared to the control. This correlated with an increase in fat-corrected milk of 1.9kg/day,” he explains. “A 0.1% improvement in protein and 0.19% increase in fat was seen in the milk constituents when comparing treatment and control group cows.

“The trial shows that — with the increased feedable dry matter and energy available in the treated forage, as well as improved dry matter intakes and milk yields — producers will see a good return on investment if they use an inoculant when making grass silage.”

– Lee Gresham, Country Manager, UK & Ireland