Globally, maize is the most used crop for ensiling and dairy production — making it an important part of many dairy operations. Growing maize and producing the best yields, and silage, possible requires producers to take into account a range of factors, such as varietal selection, seed bed preparation and good silage management practices.

Growing Maize

Field Preparation

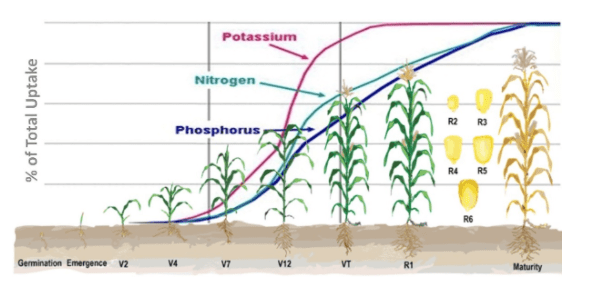

The fast growth of the plant demands an adequate supply of nutrients, typically through fertilizer applications and trace elements. Nitrogen levels are crucial to growth. Supply of nitrogen is difficult to correctly determine as plant requirements are combined through applied nitrogen and nitrogen available through soil mineralization. If nitrogen levels are too low, then leaf growth is retarded and smaller leaves are produced. As a result, less photosynthesis occurs and, ultimately, starch deposition is lower than desired. Conversely, if too much nitrogen is applied, then there is excessive leaf growth and a lower proportion of grain to stem in the final silage. Plus, there is the potential of the maize lodging during growth and the risk of silo gas being produced during the initial ensiling period. Maize also has a high demand for phosphorous for root development as well as potassium, magnesium and sulphur — all of which need to be present in a format that is plant available so timing applications of fertilizer and trace elements are critical for yield. Many trace elements are supplied through animal manure, which, if not used, needs to be taken into consideration. Typical removal rates of key elements, based on a 40T/Ha yield, are:

Nitrogen = 160 – 210 Kg / Ha

Phosphorous (as P2O5) = 55 Kg / Há

Potash (K) = 175 Kg / Ha

Key Point – correct timing and application rates of fertilizer and trace elements are critical for maize establishment and optimizing yield.

Fertilizer application should be split between starter applications and maintenance application, with nitrogen application post emergence being between the rows to avoid burning the plant. Applying nitrogen post-crop emergence has been shown to be highly beneficial in wet years.

Rapid germination of the maize is achieved through good seed bed preparation. Maize is very sensitive to soil compaction, which can enormously impact root development. If there is compaction below plough depth, soil should be subsoiled when conditions allow. The field should be initially ploughed prior to seedbed preparation to produce a fine soil quality to a depth of 8 cm. Below this, the soil should be firm (not compacted) to allow preservation of water.

Maize requires a soil pH of between 5.8 and 7.0 for growth. If the pH is lower than 6, lime should be applied. If soil analysis shows a low level of soil magnesium, a magnesium limestone should be used.

Sowing

Seed should be sown to a depth of 5 to 8 cm. If sown too shallow, then root development is impaired. The drier the soil, the deeper the seed should be sown (closer to water). Sowing should occur once the soil temperature has reached 8 to 10°C. Cultivar selection should be made based on local conditions and seed producers’ advice. Comparative assessments are run to provide specific cultivar information on expected yield of different varieties that are suited to specific locations.

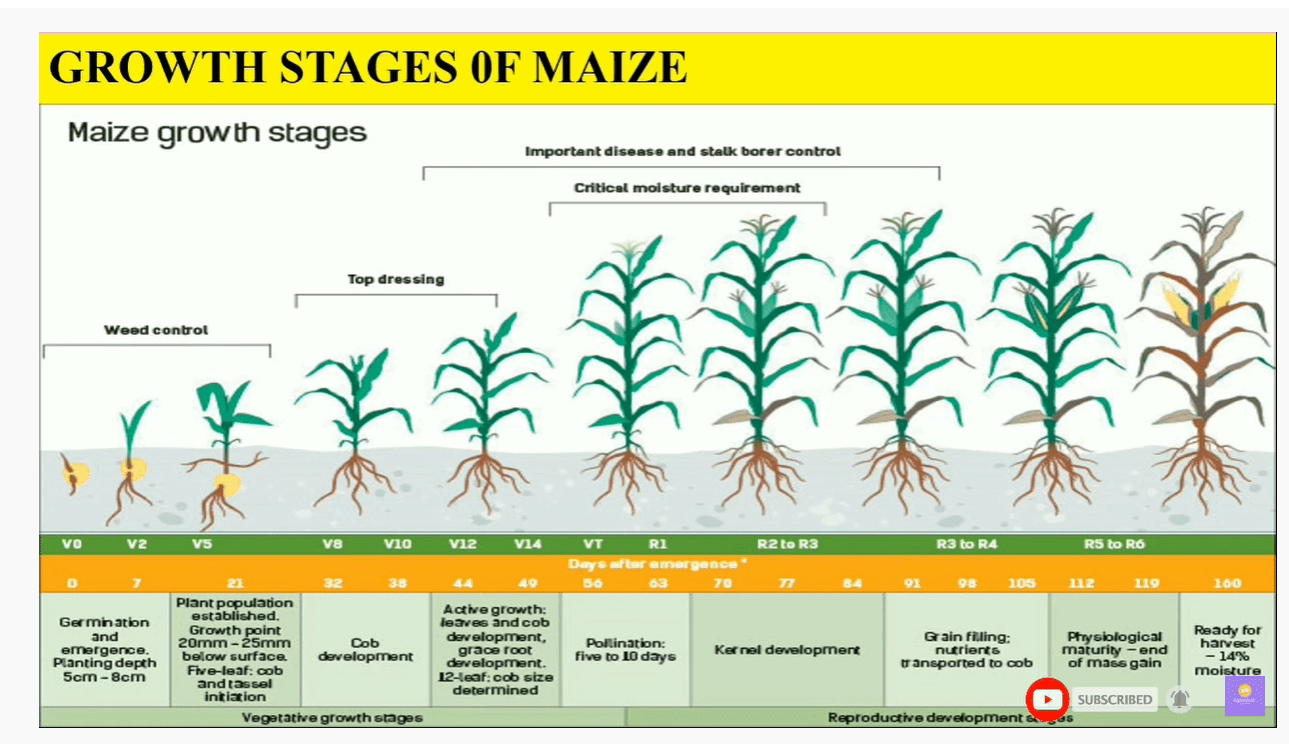

Growth stages

Growth of maize is initially very slow followed by an explosive increase in biomass production. The study tabulated below followed maize growth over a 25-year period and gives approximate dates for each stage of growth.

| Phenological Stage | Average Date | Standard deviation (days) |

| Sowing | 29 April | 4 |

| Emergence | 12 May | 4 |

| First Silk | 15 July | 7 |

| Milk Ripe | 13 August | 10 |

| Wax Ripe | 31 August | 12 |

| Physiological Maturity | 19 September | 16 |

| Harvest | 3 October | 12 |

By the end of the vegetative growth stage, the yield of the crop can be estimated. Maintenance applications of fertilizer should be applied somewhere between 30 to 45 days post planting as this coincides with the highest demand from the plant for nitrogen, phosphorous and potassium. The chart (https://www.smart-fertilizer.com/articles/cornfertilizer/) from Smart-Fertilizer shows the uptake / demand of different nutrients at different physiological stages.

Harvesting

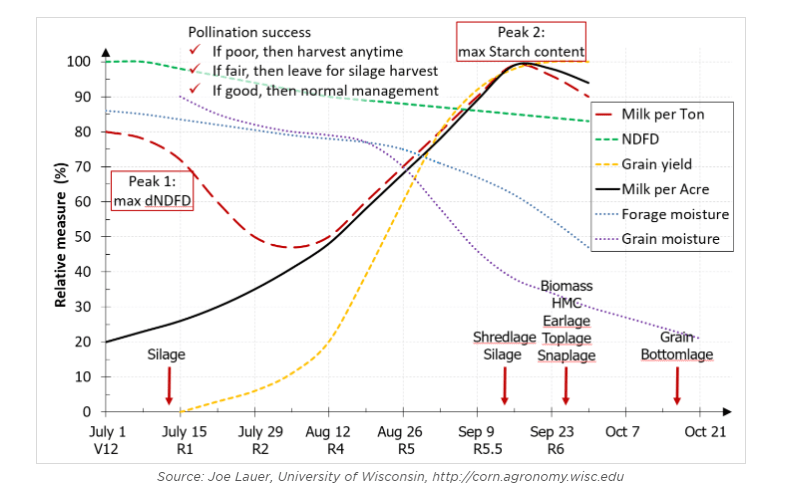

The growing maize plant can be assessed for its maturity stage by looking at the ‘milk line’ within the individual kernels of the cob. The milk line represents the line between the starchy part of the kernel and the milky part of the kernel. Historically, the growing maize would be harvested somewhere between ½ and 2/3 milk line, but it is accepted that the optimal time to harvest maize for silage is at 34.5% dry matter so the fields should be walked to assess the maturity of the growing crop across the fields. Significant feed value is lost if the maize is harvested too early (below 34% DM) but negligible value is lost if harvested up to 40% DM. So, it is best to harvest to give an average DM of 35% wherever possible (so all plants are at maximum energy content). This represents the R5.5 to R6 stage of growth (R = reproductive).

Lignin and undesirable natural occurring micro-organisms are concentrated at the base of the maize stem. Various studies have suggested different optimal cutting heights between 20 to 45 cm from the ground with no consistent evidence of the optimal height forthcoming.

When harvesting, cutting at a minimum of 20 cm from the ground will leave the highest lignin concentration of the stem in the field and help to maintain good digestibility of the ultimate silage. If the crop is lodged or soil contaminated, then the stem will be increasingly contaminated with undesirable mircoorganisms, which will not only increase dry matter losses but also significantly reduce feed value. Raising the cutting height helps to maintain overall yield at feedout and silage quality.

Standard silage will have a chop length that is defined both by its dry matter and the intended use of the silage. The dry matter should be in the region of 35%. As the dry matter increases, the chop length should decrease. At 35% DM, a standard theoretical chop length (TLC) is between 9 and 12 mm, and the kernel processor should be set to approximately 2 mm to ensure that all kernels are significantly broken (there should be no more than 1 whole kernel in 1l of chopped maize). If the kernels are not significantly damaged, then the plant enzymes cannot enter the kernel and increase the starch digestibility of the maize silage during storage. If the maize silage is to be used within an anaerobic fermenter, then the chop length should be dramatically reduced to as close to 2 mm as possible to increase the surface area. Kernel processing should be checked on a regular basis during harvesting and ensiling to ensure adequate processing.

Key point – ensure kernel processing is complete and that there is no more than 1 whole kernel in 1 L of maize, irrespective of being used for dairy or biogas

Corn silage is not typically used as a source of physical effective fiber (PEF) within the diet, but it should be noted that once the chop length reaches 9 mm and below that the silage does not offer any PEF. Alert your nutritionist if chop length is below 9 mm.

Corn silage is very prone to aerobic instability at feedout. The instability directly leads to dry matter, energy and digestibility losses from the silage due to the growth of yeast and molds, but the growth of the yeast and moulds also leads to the production of undesirable products within the silage that reduce dry matter intake by the animal.

| DM % | Time to Cross Face | Chop Length | Train Wheel | Inoculant |

| 35 | 1 day | 9 – 12mm | Yes | Magniva Classic |

| 35 | 2+ days | 9 – 12mm | Yes | Magniva Platinum 1 |

| 35 | Not Applicable | 2mm | Yes | EnergySil |

Ensiling – ensiling management of maize is important to ensure even distribution of the maize within the bunker and even compaction. The bunker should be filled in thin layers approximately 20 cm thick with appropriate compaction for the dry matter.

Naturally occurring bacteria (epiphytes) present on the forage when harvested are a combination of enterobacteria (recycling bacteria), undesirable yeast / mould and lactic acid bacteria. The efficiency and end-products of these different microorganisms is highly variable, with only the lactic acid bacteria efficiently driving the pH fall, an adequate drop in pH can help inhibit the growth of other undesirable organisms that can contribute to reduced digestibility, energy and palatability.

If the maize silage is to be used for an anaerobic digester, then the inoculant used should be specifically designed to produce higher volumes of acetic acid, which is a precursor of methane.

Sheeting of the ensiled forage should be undertaken as rapidly as possible, with all edges well sealed to minimize the risk of air ingress into the bunker. It is recommended that an oxygen barrier plastic system is used to achieve the best possible results.

Storage

Because of the difficulty in ensuring adequate, but not excessive, use of nitrogen fertilizer for optimal yield, sometimes the ensiled maize has a ‘retained’ level of nitrogen within the plant. This is concentrated at the base of the stem and can be converted from nitrogen to nitrous oxides during the initial pH fall of the forage (the first 2 – 10 days of ensiling). The gas will try to leave the silage and, if observed, then all staff and animals must be kept away from the silage until the gas stops being produced. If the gas cannot escape from the silage, then the sealing of the bunker is perfect, and the gas will be re-absorbed back into the silage where it may discolor the silage. Once it is re-absorbed into the silage, it does not represent any risk to the animal, and the silage is perfectly safe for the animal to consume.

Key point – if a brown / orange gas, with a bleach-like odor is being produced in the initial days of the fermentation, avoid all human and animal contact with the silage and contact your adviser.

Feeding

Feedout management of all silages is important. With maize silage, because of the high nutritive and energetic value of the ensiled crop, it is important to try and feed the bunker in columns or to remove the entire face at each feeding. Plastic should only be cut back sufficiently for 1 or 2 days feeding and whenever possible a frazer/defacer should be used to maintain the integrity of the bunker face.