Corn silage has a high-quality fiber content and high-energy density. It’s one of the most economical forages producers can grow based on yield and energy value. It’s also one of the easier forages to ensile. To maximize forage quality, corn should be harvested at the right maturity and dry matter (DM) content. In addition, the right cutting height, chop length and kernel processing decisions are critical to yield and quality of the resulting silage.

Maturity

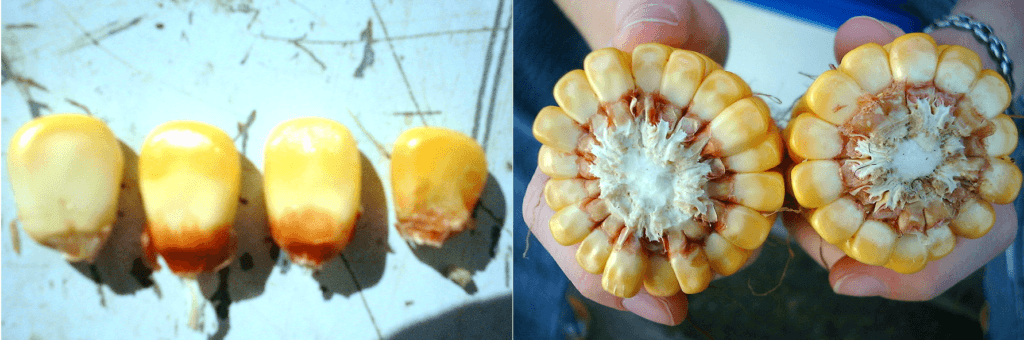

Maturity can be monitored by kernel milkline development. To maximize quality, corn should be harvested for silage when the kernels are between one-half and two-thirds milkline. Between these stages, starch content is rising and fiber digestibility is in an optimum range.

Some corn hybrids have “stay green” traits. As the kernel matures, the base of the plant remains green. This is highly desirable as grain dry down is faster than stover dry down. The stem remains green and healthy with high fiber digestibility. This introduces issues of observation of timing of maturity and elevates the need to focus harvest timing on the true dry matter of the corn plant.

Some hybrids have more moisture in the grain in proportion to the rest of the plant. Hybrids with high “stay green” characteristics have more advanced milk lines compared to the visual appearance of the plant whereas hybrids with minimal “stay green” characteristics are ready to harvest at a less milk line advanced stage. The seed supplier should provide specific advice on harvest timing.

Dry Matter

Corn is optimally harvested between 32% and 38% DM. Corn harvested for silage at greater than 32% DM will benefit from using a kernel processor or shredder processor at the time of harvest.

Achieving optimal DM for corn silage is not always possible in all areas of the world due to specific climate issues. Often, it is necessary to harvest below 30% when frost has occurred or when it is becoming increasingly difficult to work with a forager because of field conditions.

Harvesting corn at lower-than-ideal DM introduces specific issues such as:

- Crop has not achieved maximum starch deposition

- Sub-optimal energy and DM losses

- Silage will produce effluent (and greater storage losses due to effluent feed value)

- Higher risk of butyric layers within the silage

- Protein degradation

- Greater likelihood of overly fermented silage

When harvesting corn silage below 30% DM, it is generally recommended that producers should:

- Avoid kernel processing

- Raise the chop length of the forage to 0.8 to 1 inch, or 20 to 25 mm

- Avoid overcompacting the forage (do not use train wheel compactors)

Chop Height

Select a chop height between 4 to 8 inches, or 10 to 20 cm., for maximum yield or around 18 inches, or 45 cm., for higher nutritive value. BMR corn hybrids do not need to be chopped higher than about 8 inches, or 20 cm.

Chop Length

A short chop length facilitates high packing density and minimizes air infiltration into the silo, while a longer chop length adds effective fiber in the diet. The correct chop length for corn depends on whether the crop is harvested conventionally, with or without a kernel processor (KP), or with a shredding processor. Much of the advantage of processing corn silage is due to better kernel breakage and, therefore, higher availability of starch for digestion. Depending on the feeding system, when a higher percentage of corn silage is included in the total ration then, a higher chop length should be used. Chop length is increasingly important as a higher percentage of the forage is composed of corn silage.

In general, kernel-processed corn should be chopped between 0.5 to 0.75 inches, or 13 to 19 mm. An average theoretical length of cut (TLC) of 1.18 inches, or 30 mm, is recommended for shredding processors, depending on the equipment used. Corn that isn’t processed or shredded should be chopped at a TLC of 0.25 inch or 0.5 inch, or 6 to 13 mm. Corn harvested for silage at greater than 32% DM should be processed to maximize utilization by the animal.

The use of shredding processors has been multiplied. The processor shreds the corn stalk into longer pieces than with KP, providing more physically effective fiber, while the chop length is longer, 1 to 1.18 inches, or 26 to 30 mm, at 32% to 38% DM and the processing rolls are set closer to better crush the kernels.

Actual chop length can be monitored in the field by using NASCO’s® Penn State Forage Particle Separator. Read more about this tool here.

Kernel Processing

Kernel processing influences the energy available in the rumen. Much of the advantage of processing corn silage is due to better kernel breakage and, therefore, higher kernel processing scores (KPS).

The higher the DM, the more important is to adequately process the grain. When adequately processed, 70% of all grains should be less than 0.19 inch, or 4.75 mm. In a quarter gallon, or 1 L, of grain, less than three or four kernels should be unbroken or half broken.

Learn more about forage inoculant choices for corn/maize silage.

Be sure to create silage safely. Learn more here.